Factory Supply High Pit Tile Profile UPVC Roofing Sheet

Type: High Pit Profile UPVC Roofing Sheet

Material: Polyvinyl chloride resin, anti-UV agent and other chemical additives

Thickness: 1.2 to 3.0mm

Length: Customized,

Factory Supply Of High Pit Tile Profile Upvc Roofing Sheets, Offering Durability And Efficient Water Drainage

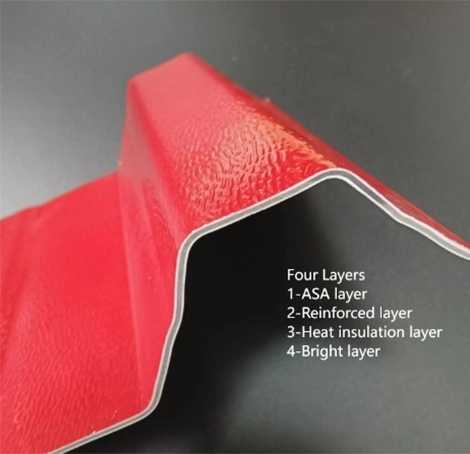

Uniko High Pit Profile UPVC Roofing Sheet, using PVC (polyvinyl chloride resin) as main material, mixing anti-UV agent, shielding agent, antioxidant, modifier and other super weathering chemical ingredients.

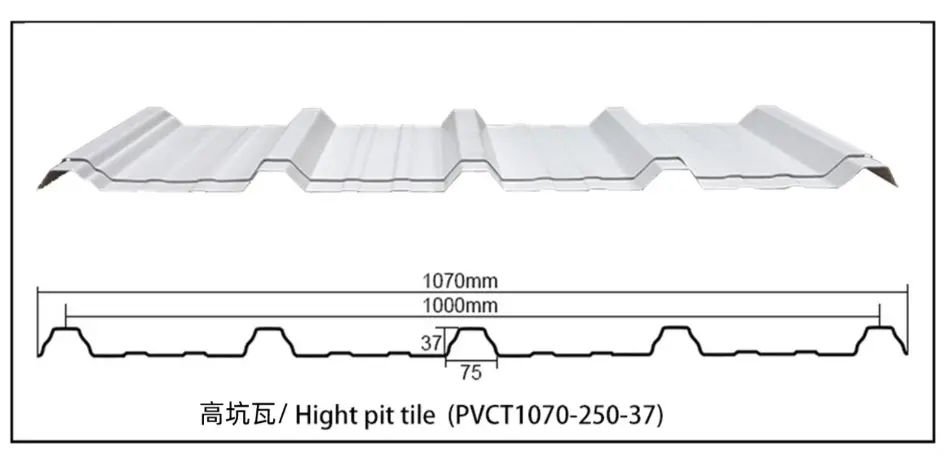

Type | High Pit Profile UPVC Roofing Sheet |

Material | Polyvinyl chloride resin, anti-UV agent and other chemical additives |

Thickness | 1.2 to 3.0mm |

Length | Customized, <5.8 meters for 20' container,<11.8 meters for 40'container |

Width | 1070mm |

Wave Spacing | 250mm |

Wave Height | 37mm |

MOQ | 20'container QTY(about 4500~6000 square meters) |

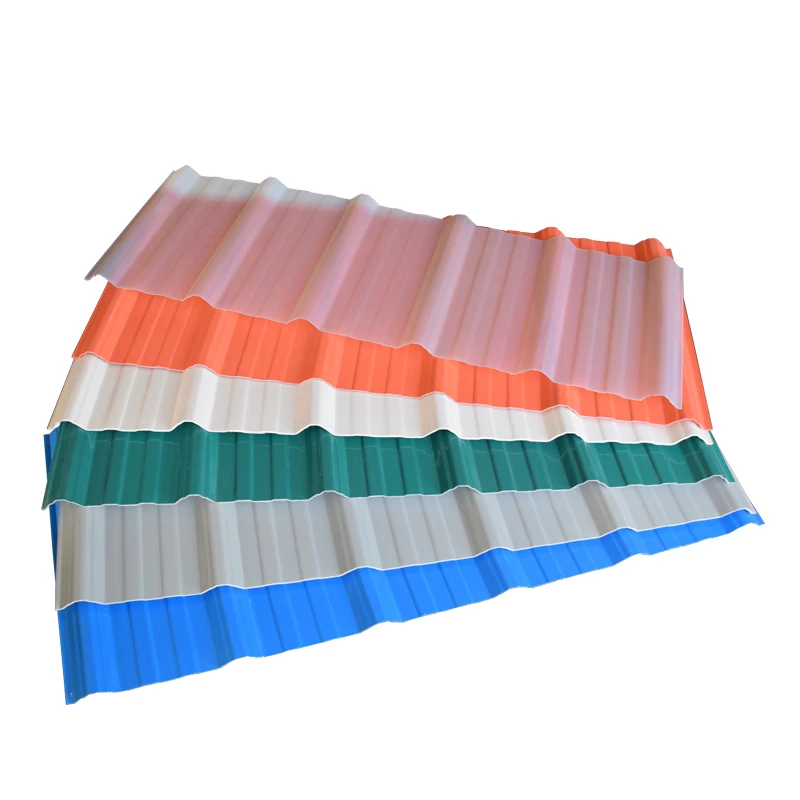

Color | White, Red, Blue, Green, Gray |

Accessories | 4 sets screws and caps per square meters |

Application | Factory Building, Warehouse, Farm's Market, Mobile Room, etc. |

Product Feature for UPVC Roofing Sheet

1. Weather resistant / Heat insulation / Thermal insulation performance:

Heat conductivity coefficient:0.325W/m.k ( Eg. outdoor 40°,indoor 32°)

2. Anti-Corrosion:

Soak in salt,alkali and various acids below 60% for 24 hours without chemical reaction,the same type, non-discolouring , no crack.

3. Sound -proof:

Under the influence of external noise such as heavy rain and strong wind ,it has good noise absorption effect.

4. Super-strong impact resistance:

After testing, a kilogram of steel ball falls freely from a height of three meters,and the product will not crack.

5. Flame resistance/Strong fire resistance:

Synthetic resin tile main materials in PVC resin oneself belong to flame retardant materials,the national fireproof department to examine fire performance reach even over B1 level.

6. Insulating property:

The insulation products are still intact after electric shock,and are safer to use in mountainous areas and regions with high lightning incident.

7. Easy installation:

Light weight,assemble and unassemble (each square meter need 4-6 waterproof accessories)

8. Environment friendly /Green and environmental protection:

No asbestos or any other radioactive elements,recyclable,completely in conformity with environmental protection

Foshan Uniko Building Materials Co.,Ltd

Established in 2014 and located in Foshan City, Guangdong Province, FOSHAN UNIKO BUILDING MATERIALS CO.,LTD is a large-scale manufacturer dedicated to the production, sales and research and development of ASA synthetic resin tiles, ASA synthetic classical tiles, ASA-UPVC composite anti-corrosive tiles, APVC composite heat-insulating tiles,UPVC anti-corrosive heat-insulating tiles,Polycarbonate Sheet, WPC Wall Panel and other new roofing building materials.

Product Application

PVC roof tile could be widely replacing metal, wood and stone as structural products,building materials, decorative material and so on. It can be used in farm construction, paper mill construction, site construction, warehouse construction, factory construction, garage construction, winery, brick factory, chemical factory and other almost all kind of environmental project.

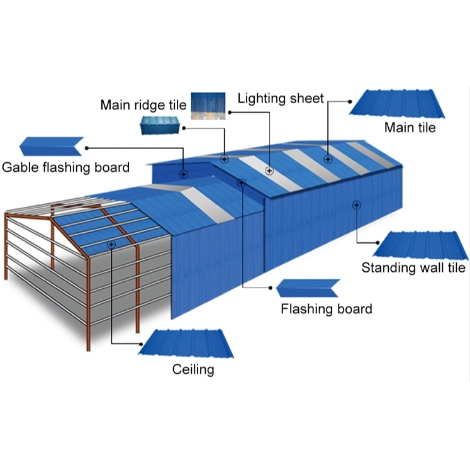

Installation Instructions

1/ All the roof tile should be fixed by our supplied special waterproof accessories.

2/ Every sheet should have 4-6 waterproof accessories with each square meter, and the screw must always be at the crest of waves and can not be fastened too tightly or too loosely. Finger can not untie is okay.

3/ For top ridge tile, vertical overlaps and eaves, waterproof accessories must be fixed at every wave crest.

4/Sidewall without using flashing board should be fastened by steel straps in heavy windy area.

5/ For wall sheet, the overlaps between two purlin should be fixed by two rivets.

6/ Sealing ring should be used under the sheet if fixing by hooks, the screw nuts should be tightened

2/ Every sheet should have 4-6 waterproof accessories with each square meter, and the screw must always be at the crest of waves and can not be fastened too tightly or too loosely. Finger can not untie is okay.

3/ For top ridge tile, vertical overlaps and eaves, waterproof accessories must be fixed at every wave crest.

4/Sidewall without using flashing board should be fastened by steel straps in heavy windy area.

5/ For wall sheet, the overlaps between two purlin should be fixed by two rivets.

6/ Sealing ring should be used under the sheet if fixing by hooks, the screw nuts should be tightened

Production Process

01

Mix well

02

Mix well

03

Thermoform

process

process

04

Cut sheet

05

Pack for

storage

storage

06

Deliver from

storage

storage

Our company has passed 1S09001 quality system certifcation and applied for a number of patents to protect our technological achievements and the uniqueness of our products.

Get You Quotation Now

Tell us what you are searching for ? The more details you give, the more efficient we are.Factory Supply High Pit Tile Profile UPVC Roofing Sheet

Type: High Pit Profile UPVC Roofing Sheet

Material: Polyvinyl chloride resin, anti-UV agent and other chemical additives

Thickness: 1.2 to 3.0mm

Length: Customized,

You may also like

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

sales01@syrooftile.com

sales01@syrooftile.com +86 13924808361

+86 13924808361